Stay updated with the latest trends in the pharmaceutical world—from breakthrough research and industry innovations to business strategies and

manufacturing insights. Our featured blog posts offer valuable knowledge and expert commentary to help you stay ahead in the rapidly evolving healthcare landscape.

Top 5 Reasons to Choose a Capsule Manufacturer in India

Why India is a Global Choice for Capsule Manufacturing

Introduction

In today’s competitive pharmaceutical industry, manufacturing quality and efficiency can define the success or failure of a brand. For capsule production especially, companies require partners who can provide consistency, scalability, and compliance at the right cost. Instead of building in-house facilities, many companies now choose to outsource capsule manufacturing.

Among global destinations, India has become a preferred choice for capsule outsourcing, serving as a reliable hub for international pharmaceutical companies. Manufacturers like Vtv Formulations combine global-quality standards with affordability, making India a smart and strategic option for capsule production.

India: A Global Leader in Pharmaceutical Manufacturing

India is widely regarded as the “pharmacy of the world”. Ranked among the largest producers of medicines by volume, India supplies affordable and high-quality pharmaceuticals to more than 200 countries. Capsule manufacturing has become one of its strongest pillars thanks to:

- Modern pharmaceutical clusters with state-of-the-art facilities

- A highly skilled scientific workforce

- Government incentives to promote pharmaceutical exports

- Strong adherence to international regulatory standards

This ecosystem ensures that Indian capsule manufacturers deliver products that are both cost-effective and globally trusted.

High Standards of Quality Assurance

For pharmaceutical brands, product quality is non-negotiable. Indian capsule manufacturers implement multi-step quality checks—from sourcing of raw materials to final testing—to ensure capsules are consistent, effective, and safe.

Companies like Vtv Formulations guarantee that capsules pass through:

- Rigorous raw material testing

- In-process monitoring

- Final-stage product validation against international benchmarks

GMP Certification

Many Indian capsule manufacturers operate under WHO-GMP certification, which ensures that every step of the production process follows international Good Manufacturing Practices. GMP certification demonstrates compliance with strict hygiene, safety, and process control standards—vital for international business expansion.

High-Quality Raw Materials

The base of capsule effectiveness lies in the quality of ingredients. Indian manufacturers use premium-grade gelatin, HPMC, and other excipients, ensuring every capsule meets global safety and performance requirements. Vtv Formulations emphasizes reliable supplier networks and thorough raw material verification before production begins.  |

10 Tips for Finding the Right Ointment Contract Manufacturer in India

India’s pharmaceutical industry is one of the most dynamic and rapidly growing sectors in the global healthcare landscape. Over the past decade, the country has not only become a major supplier of generic medicines but also a trusted hub for third-party and contract manufacturing. Among the numerous product categories, ointment manufacturing has gained tremendous demand due to its broad application in therapeutic, dermatological, cosmetic, and herbal products. From antibacterial creams to soothing gels, ointments are integral to patient care and wellness routines.

For companies looking to expand their product portfolios, partnering with a reliable ointment contract manufacturer in India can be a game-changer. It allows them to access advanced production technologies, quality assurance systems, and economies of scale without investing heavily in infrastructure. However, with hundreds of manufacturing firms operating across India—each claiming superior quality and faster delivery—the real challenge lies in finding the one that aligns perfectly with your business objectives, regulatory expectations, and brand identity.

Choosing the wrong manufacturing partner can have severe consequences. Poor formulation stability, non-compliance with regulations, delayed deliveries, or substandard packaging can harm not just your business but also consumer trust. Conversely, the right partner acts as an extension of your brand, ensuring every batch produced reflects your company’s commitment to excellence. Therefore, careful evaluation and due diligence are non-negotiable steps before finalizing any contract.

In this comprehensive guide, we’ll outline ten essential tips for identifying a trustworthy ointment contract manufacturer in India. We’ll cover everything—from assessing reputation and technical expertise to understanding capacity, pricing transparency, and communication efficiency. Whether you are a startup entering the pharmaceutical market or an established brand seeking to outsource production, these guidelines will help you make an informed, confident decision.

Let’s explore how to turn your ointment manufacturing vision into a sustainable success story by selecting a partner that shares your standards of quality, trust, and innovation.  |

How to Find the Best Third-party Manufacturer for Your Soft Gel Product

Introduction and Understanding Third-Party Soft Gel Manufacturing

Introduction

Finding the right third-party manufacturer for your soft gel product is a crucial step in ensuring quality, compliance, and efficiency. A reliable manufacturer can help bring your product to market smoothly while meeting industry standards. This guide will help you navigate the essential factors involved in choosing the right third-party manufacturing partner for your soft gel line.

What is Third-Party Manufacturing?

Third-party manufacturing, also known as contract manufacturing, is the process of outsourcing product production to a specialized manufacturer. This method is widely used in the pharmaceutical, nutraceutical, and supplement industries, especially for soft gels, due to their technical complexity and stringent compliance requirements.

By choosing third-party manufacturing, companies can bring products to market more efficiently, focusing on branding and distribution while leaving the production process in the hands of experts.

Why Choose Third-Party Manufacturing for Soft Gel Products?

Outsourcing soft gel manufacturing brings several advantages:

-

Cost-Effectiveness: Reduces investment in machinery, workforce, and infrastructure.

-

Expertise and Experience: Access to professionals skilled in soft gel production, including formulation and encapsulation.

-

Regulatory Compliance: Ensures that products meet national and international quality and safety standards.

-

Focus on Core Competencies: Brands can focus on marketing, sales, and distribution.

-

Faster Time-to-Market: Benefit from the manufacturer’s existing processes and capabilities.  |

Third Party Manufacturing Pharmaceuticals In India

Understanding Third-Party Pharmaceutical Manufacturing

In today's rapidly evolving pharmaceutical landscape, third-party manufacturing has become a cornerstone for scalable, cost-effective growth. It offers companies—whether startups or established brands—a chance to launch or expand their product lines without the enormous investment required to set up their own manufacturing facilities.

What is Third-Party Manufacturing?

Third-party pharmaceutical manufacturing, also known as contract manufacturing, refers to an arrangement in which a company outsources the production of its medicines to a certified pharmaceutical manufacturer. This means that a product can be developed, manufactured, and packaged under your brand name while the actual production is carried out by another firm.

This model is particularly effective in the pharmaceutical sector, where product development and manufacturing require complex infrastructure, rigorous quality controls, and regulatory compliance.

How the Process Works

-

Contract Signing: The brand owner and manufacturer agree on terms, timelines, and responsibilities.

-

Product Selection: You can choose from existing formulations or request a custom one.

-

Documentation Submission: Required licenses like Drug License, GST Certificate, and product details are submitted.

-

Production & Testing: The manufacturer produces the batch under strict quality guidelines.

-

Branding & Packaging: Products are labeled and packed with your company’s brand.

-

Distribution: Finished goods are shipped for marketing and retail.

Why It Matters

This business model removes the burden of manufacturing from the brand owner. It allows you to focus on marketing, branding, and distribution, while your manufacturing partner ensures that regulatory compliance, quality control, and timely production are taken care of.  |

How to Choose the Best Third-Party Manufacturer for eye drops in India for Your Product

Why SMEs Need Third-Party Manufacturers & Key Considerations

Small and Medium Enterprises (SMEs) are the backbone of many economies, including India’s. They create jobs, foster innovation, and drive local economic growth. However, running an SME is no easy feat. One of the biggest challenges entrepreneurs face is identifying a reliable third-party manufacturer—especially for niche pharmaceutical products like eye drops. These manufacturers can help SMEs avoid the heavy investments needed for production facilities while allowing them to focus on marketing, branding, and distribution.

But finding the right manufacturing partner requires more than a quick search. It’s essential to consider a variety of factors that will influence product quality, timelines, and long-term success.

Key Factors to Consider :

- Product Design : Your product’s design is critical. A quality manufacturer will offer not just production, but design support. They should help you refine packaging, labeling, and even viscosity or dosage mechanisms for eye drops if required.

- Materials : Different materials come with different price points, functionalities, and compliance issues. For eye drops, choosing between plastic (for dropper bottles), glass (for premium feel or sensitive formulations), and even eco-friendly alternatives matters. Your manufacturer should offer clarity and flexibility.

- Timelines : Delays can disrupt market launches and client trust. Choose a manufacturer with realistic timelines and transparent production schedules. Make sure they can scale if demand increases suddenly.

- Pricing : Affordability matters, but so does quality. Look for a manufacturer who provides value, not just low costs. Pricing should be broken down clearly, including setup charges, per-unit costs, packaging, and regulatory compliance fees.

|

Nasal Spray Third Party Manufacturer

Nasal sprays have become an essential tool in modern medicine, offering a highly effective and convenient method for delivering medications directly to patients. Unlike oral medications, nasal sprays deliver drugs through the nasal mucosa, which allows them to bypass the gastrointestinal tract and the liver’s first-pass metabolism. This means faster absorption, more immediate effects, and fewer systemic side effects. As a result, nasal sprays are particularly useful for conditions that require quick relief, including seasonal allergies, sinus infections, colds, and asthma. Their role has even expanded to hormone therapy and the delivery of certain vaccines and psychiatric medications.

One of the main advantages of nasal sprays is their versatility. They can contain antihistamines for allergy relief, decongestants for sinus blockages, corticosteroids for inflammation, or pain-relief agents for rapid symptom control. Additionally, the convenience factor cannot be overstated. Unlike tablets or syrups, nasal sprays require no water and can be administered discreetly, making them ideal for busy individuals or situations where immediate relief is necessary. For example, someone experiencing a sudden migraine or an asthma flare-up can benefit from a metered-dose nasal spray almost instantly, whereas oral medications may take 30–60 minutes to become effective.

Another advantage of nasal sprays is their ability to target specific areas, such as the sinuses, providing localized relief while reducing systemic exposure. This targeted delivery is particularly valuable for patients with chronic sinusitis or nasal allergies. Innovations in formulation technology have further expanded their potential. Today, nasal sprays are not only limited to symptomatic relief but are also being used for hormonal therapies, such as desmopressin for diabetes insipidus, and emerging treatments like ketamine sprays for depression.

Moreover, nasal sprays have gained popularity due to their travel-friendly and non-invasive nature. Patients who are needle-averse or have difficulty swallowing tablets can benefit significantly. With the rise of nasal vaccines, including influenza and COVID-19 nasal vaccines, the demand for reliable nasal spray products has only increased. For pharmaceutical brands, this growing demand translates into ample opportunities, but success depends heavily on choosing the right manufacturing partner who can maintain consistent quality and compliance.  |

What Is a Pharmaceutical Syrup Contract Manufacturer and Why Should Your Company Consider One

Understanding Pharmaceutical Syrup Contract Manufacturing

Pharmaceutical manufacturing is a highly specialized field that requires precision, compliance, and expertise across multiple stages—from research and development to large-scale production and distribution. One critical area within this field is the manufacturing of pharmaceutical syrups—a liquid dosage form widely used for pediatric, geriatric, and general patient care due to its ease of administration and patient acceptability.

As pharmaceutical companies strive to stay competitive and agile in today's fast-moving market, they often seek contract manufacturers to handle syrup production. But what does this mean, and why is it important?

A pharmaceutical syrup contract manufacturer is a third-party organization that produces liquid pharmaceutical formulations—such as cough syrups, multivitamin tonics, antacids, and antibiotic suspensions—on behalf of a pharmaceutical company (the brand owner). These companies are often equipped with state-of-the-art facilities, certified quality control labs, and compliance with standards such as WHO-GMP, ISO, and occasionally USFDA.

Why Syrups Require Specialized Manufacturing

Liquid pharmaceuticals come with unique production challenges:

- They require accurate formulation to ensure uniformity and dosage accuracy.

- They are more sensitive to microbial contamination.

- They demand specialized packaging (usually amber bottles or PET containers with proper sealing).

- They often need added preservatives, flavoring agents, and stabilizers.

Unlike solid dosages like tablets or capsules, syrups require stringent quality control, sterilization, and viscosity control. Only experienced manufacturers with the proper infrastructure can ensure batch consistency, safety, and efficacy.

Who Needs a Syrup Contract Manufacturer?

Syrup contract manufacturers are ideal for:

- Small or medium-sized pharma brands looking to expand product lines without building a plant.

- Startups needing small-scale trial production before scaling.

- Large pharmaceutical companies seeking to outsource high-volume production or overflow batches.

- Global companies entering the Indian market through local manufacturing partners.

- Product formulation and development

- Batch testing and documentation

- Primary and secondary packaging

- Regulatory support (CDSCO, FSSAI, AYUSH, etc.)

- Logistics and warehousing

|

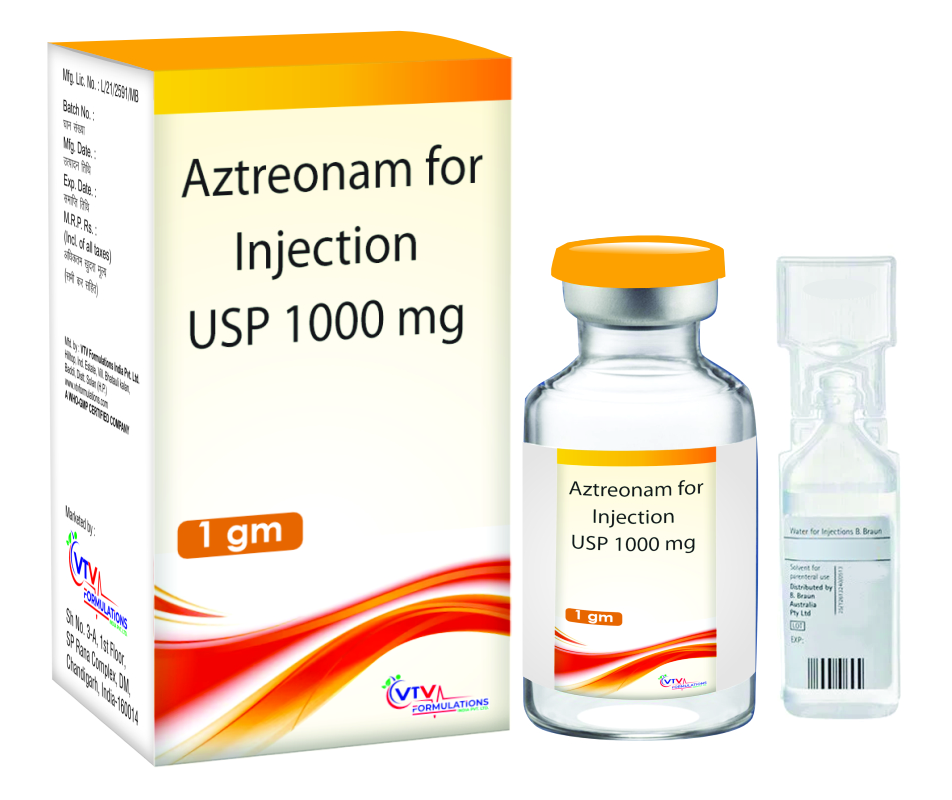

A Guide to Finding the Best Third-Party Injection Manufacturers

Understanding Third-Party Injection Manufacturing

What is a Third-Party Manufacturer?

In pharmaceutical manufacturing, third-party manufacturers (also known as contract manufacturers) are external companies that produce medicines or medical products—like injections—on behalf of another company. These companies specialize in formulation, filling, sterilization, and packaging of injectable drugs, ensuring the highest levels of safety, consistency, and compliance with government regulations.

Pharmaceutical injections often involve strict production controls because they are introduced directly into the body. Because of this, many pharma companies outsource injection production to facilities already equipped with sterile environments, skilled staff, and advanced technology.

Why Third-Party Manufacturing is Growing

The popularity of third-party manufacturing has grown significantly due to rising demand for:

- Affordable healthcare in emerging markets

- Flexible production models that scale with demand

- Regulatory compliance without heavy upfront investment

Outsourcing production is especially appealing for startups, mid-sized pharmaceutical firms, and even large corporations expanding their portfolios. It enables a leaner business model while maintaining high standards of output.

Who Should Consider Third-Party Manufacturing?

- New pharma companies lacking in-house production facilities

- Exporters entering new international markets

- Healthcare brands looking to diversify with injectable formulations

- Hospitals/clinics launching private-label injectables

By partnering with a specialized manufacturer, companies can enter the market faster and more competitively, focusing on branding, distribution, and innovation while the manufacturing is handled professionally.  |

A Guide on How to Find the Right Contract Manufacturer for Your Injection in India

Managing Your First Injection Order — Balancing Costs and Quality

Securing your first injection molding order is an exciting milestone for any business. It signals that your product idea is moving from the design stage into real-world production. However, the transition is rarely smooth. Suppliers and manufacturers often suggest modifications—sometimes for technical feasibility and sometimes for cost optimization. For example, they may recommend altering wall thickness, changing the resin type, or adjusting dimensions to ensure proper mold flow. While these changes may seem minor, they can significantly impact costs, timelines, and even the end-user experience.

The biggest challenge at this stage is balancing quality with affordability. New businesses in particular may feel pressured to cut costs wherever possible, but compromising on quality can lead to higher rejection rates, product recalls, or brand reputation issues down the line. To strike the right balance, it is essential to understand where the money goes in injection molding:

- Raw Materials – Resin choice drives both quality and cost. Commodity plastics like polypropylene (PP) or polyethylene (PE) are cheaper, while engineering plastics such as ABS or polycarbonate are more expensive but necessary for high-performance products.

- Tooling Costs – Molds are the most significant upfront investment. A simple single-cavity aluminum mold may cost ₹50,000–₹1,00,000, while a complex steel multi-cavity mold can exceed ₹10,00,000. The quality of the mold directly affects consistency and lifespan.

- Labor and Machine Costs – Running advanced injection molding machines requires trained operators. Though India offers lower labor costs compared to Western countries, specialized skills and setup times still contribute to expenses.

- Quality Control – Inspection and testing safeguard your product against defects. Cutting corners here often backfires, resulting in wastage, rework, or failed shipments.

- Packaging and Logistics – Often underestimated, these costs can add up, especially if products need export-quality packaging or cold-chain transportation.

Maintaining quality is not optional in injection molding. Small errors in temperature control, pressure regulation, or cycle timing can result in warped parts, sink marks, or weak joints. Defects not only increase costs due to scrap but also delay deliveries. This makes working closely with your manufacturer critical. Establish clear tolerances, inspection protocols, and approval processes before mass production begins.

India is a growing hub for injection molding, offering cost savings, skilled labor, and government support. Still, navigating your first order requires careful planning. The best approach is to collaborate with the manufacturer from the start, define non-negotiables (such as safety standards), and remain flexible where design tweaks can save money without hurting quality.  |

Third Party Manufacturing Pharmaceuticals In India

Understanding the Concept of Third-Party Pharmaceutical Manufacturing

What is Third-Party Pharmaceutical Manufacturing?

Third-party pharmaceutical manufacturing is a business model where a certified manufacturing company produces medicines on behalf of another company, typically under the client’s brand name. This approach allows businesses—especially marketing companies or startups—to offer high-quality pharmaceutical products without owning or operating a manufacturing facility.

Instead of handling the complexities of production, companies can outsource to an experienced manufacturer, focusing their efforts on branding, distribution, and business development. This significantly lowers the capital required for entering or scaling in the pharmaceutical industry.

Why Do Companies Opt for This Model?

The model is cost-effective and efficient. Third-party manufacturing eliminates the need for significant investments in land, machinery, regulatory compliance, and labor. It also shortens the time required to launch new products in the market.

As a result, businesses gain the advantage of faster market entry, operational flexibility, and reduced financial burden. They can focus on core competencies like sales and marketing while relying on professional manufacturers to handle production and quality assurance.

How Does the Process Work?

Third-party manufacturing generally follows a structured workflow:

-

Agreement: The client signs a manufacturing agreement with a WHO-GMP-certified company outlining deliverables, terms, and timelines.

-

Product Selection: Clients can choose from the manufacturer’s product list or request customized formulations to match specific market needs.

-

Regulatory Support: Manufacturers assist with regulatory documentation, stability studies, and compliance with drug control authorities.

-

Manufacturing & Testing: Medicines are produced using high-end technology and tested thoroughly for quality, safety, and efficacy.

-

Branding & Packaging: Products are labeled and packed under the client’s brand name as per design specifications.

-

Delivery: The finished products are dispatched for distribution, either domestically or internationally.

Who Benefits From This Approach?

This model benefits:

-

Pharma startups entering the market without heavy capital.

-

Marketing companies focused solely on branding and sales.Global firms looking for cost-effective production in India.

-

Firms expanding their product portfolio quickly and economically.

Third-party manufacturing is a strategic solution for companies aiming to build or expand a pharmaceutical brand with limited manufacturing capacity.  |