10 Tips for Finding the Right Ointment Contract Manufacturer in India

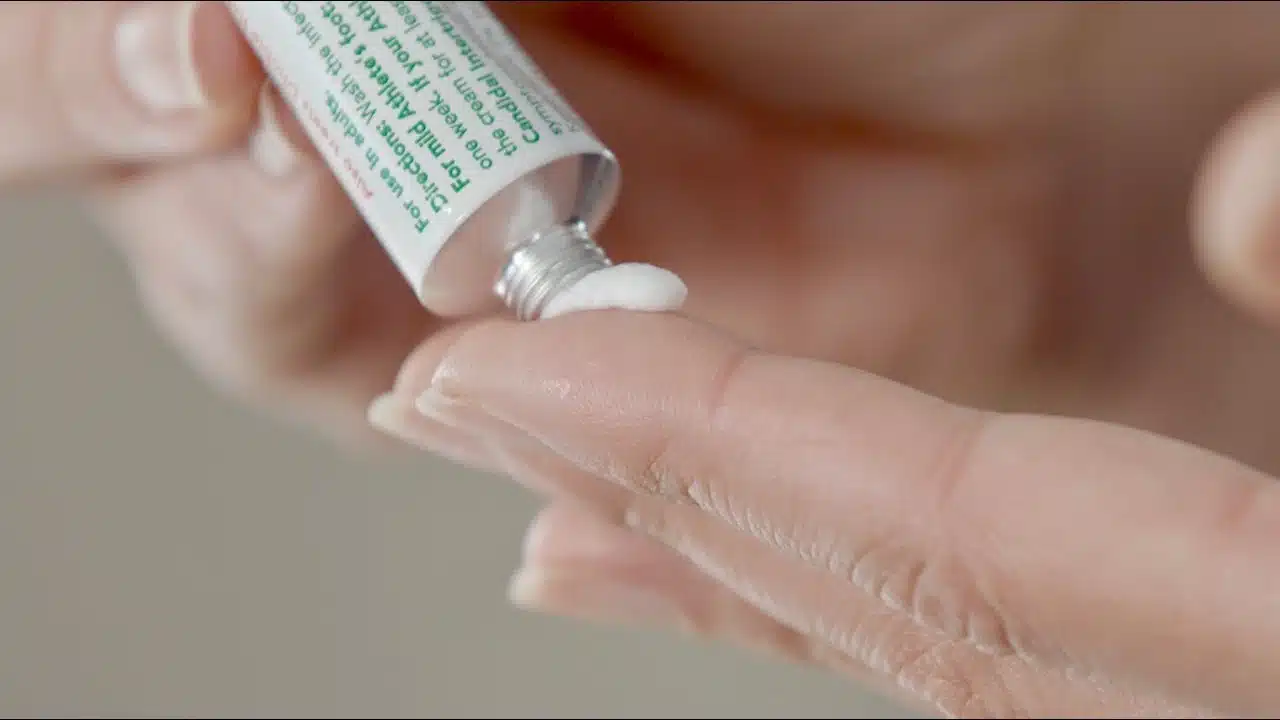

India’s pharmaceutical industry is one of the most dynamic and rapidly growing sectors in the global healthcare landscape. Over the past decade, the country has not only become a major supplier of generic medicines but also a trusted hub for third-party and contract manufacturing. Among the numerous product categories, ointment manufacturing has gained tremendous demand due to its broad application in therapeutic, dermatological, cosmetic, and herbal products. From antibacterial creams to soothing gels, ointments are integral to patient care and wellness routines.

For companies looking to expand their product portfolios, partnering with a reliable ointment contract manufacturer in India can be a game-changer. It allows them to access advanced production technologies, quality assurance systems, and economies of scale without investing heavily in infrastructure. However, with hundreds of manufacturing firms operating across India—each claiming superior quality and faster delivery—the real challenge lies in finding the one that aligns perfectly with your business objectives, regulatory expectations, and brand identity.

Choosing the wrong manufacturing partner can have severe consequences. Poor formulation stability, non-compliance with regulations, delayed deliveries, or substandard packaging can harm not just your business but also consumer trust. Conversely, the right partner acts as an extension of your brand, ensuring every batch produced reflects your company’s commitment to excellence. Therefore, careful evaluation and due diligence are non-negotiable steps before finalizing any contract.

In this comprehensive guide, we’ll outline ten essential tips for identifying a trustworthy ointment contract manufacturer in India. We’ll cover everything—from assessing reputation and technical expertise to understanding capacity, pricing transparency, and communication efficiency. Whether you are a startup entering the pharmaceutical market or an established brand seeking to outsource production, these guidelines will help you make an informed, confident decision.

Let’s explore how to turn your ointment manufacturing vision into a sustainable success story by selecting a partner that shares your standards of quality, trust, and innovation.

Why Choosing the Right Manufacturing Partner Matters

The pharmaceutical manufacturing ecosystem operates on precision, quality control, and trust. When you outsource your ointment production, you are essentially putting your brand’s reputation in another company’s hands. Therefore, your chosen partner must not only meet your technical requirements but also reflect your business ethics and reliability. A manufacturer’s quality standards, documentation systems, and responsiveness can directly impact your credibility in the market.

When evaluating manufacturers, focus on key areas such as expertise, scalability, compliance, and communication. The right balance among these ensures your long-term success while maintaining regulatory harmony and consistent supply.

Assess Their Industry Experience and Reputation

A company’s reputation is often a reflection of its operational excellence and client satisfaction. Before signing any agreement, take time to research their market standing.

- Years of Operation: A manufacturer with over a decade of experience in ointment production understands formulation stability, sterilization, and packaging intricacies better than newer firms.

- Client References: Ask for a few client contacts and speak directly to learn about their experience, reliability, and after-sales support.

- Online Reviews: Platforms like IndiaMART, TradeIndia, and Google Business reveal genuine feedback from clients on delivery timeliness, product consistency, and professionalism.

- Therapeutic Specialization: Some firms focus on dermatology, while others excel in herbal or cosmetic ointments. Match their expertise to your target segment.

- Certifications & Awards: Recognitions or government accreditations indicate strong compliance and ethical business practices.

A strong reputation demonstrates the company’s ability to deliver consistently and handle market challenges effectively.

Check Packaging and Delivery Capabilities

Packaging plays a critical role in determining product stability, appeal, and consumer safety. A professional manufacturer should offer both flexibility and compliance in packaging solutions.

-

Variety of Packaging: Ensure the availability of aluminum tubes, laminated tubes, jars, and pump bottles suited to your ointment type.

-

Labeling Customization: The manufacturer should support private labeling, design integration, and multilingual packaging for exports.

-

Compliance Standards: Packaging must adhere to CDSCO, WHO-GMP, or export country guidelines.

-

Timely Dispatch: Efficient logistics systems and in-house storage facilities help in meeting supply schedules without disruption.

-

Batch Traceability: Each batch should be barcoded or coded for easy tracking and recall management.

Packaging excellence reflects the company’s attention to detail and commitment to your brand image, ensuring that every product reaching consumers maintains its intended quality and appeal.

Technical and Regulatory Excellence

Technical precision, documentation, and regulatory compliance form the foundation of any successful ointment manufacturing partnership. A manufacturer that invests in modern infrastructure, R&D, and quality control systems is far more likely to meet your long-term business requirements and global standards.

- Verify Certifications and Licenses- Ensure the manufacturer holds WHO-GMP, ISO 9001, ISO 22716, and CDSCO-approved drug manufacturing licenses. These certifications confirm that the facility operates under stringent quality norms, ensuring consistency and safety.

- Inspect the Manufacturing Facility- Visit the site or request a virtual tour to observe cleanliness, workflow, and automation. An organized and hygienic plant reflects process control, while disorganized spaces often signal poor quality management.

- Evaluate R&D and Formulation Capabilities- Ask whether the company offers formulation support, prototype creation, and stability testing. A strong R&D setup allows innovation in texture, absorption, and therapeutic performance.

- Examine Testing and Quality Control Labs- Confirm the presence of in-house QA and QC labs equipped with microbiological testing units. Regular batch testing ensures your products remain effective and contamination-free.

- Check for Scalable Production Capacity- Understand monthly and annual capacity, along with their flexibility to handle sudden demand surges. A scalable partner ensures uninterrupted supply during product growth or new launches.

- Review Documentation Systems- Each batch should come with detailed COA, MSDS, and BMR records. Comprehensive documentation supports traceability, audits, and regulatory compliance.

- Focus on Technological Upgradation- The use of automated filling machines, climate-controlled storage, and computerized monitoring adds to precision. Technology reduces manual errors and enhances efficiency in large-scale operations.

- Ensure Stability and Compatibility Testing- Ointments must remain stable under different environmental conditions. Your manufacturer should conduct long-term and accelerated stability studies to verify product performance.

- Ask About Environmental Compliance- Sustainable operations like waste treatment, eco-friendly packaging, and water recycling show responsible manufacturing. Choosing such a partner strengthens your brand’s reputation in environmentally conscious markets.

- Regular Third-Party Audits- Reliable manufacturers undergo independent audits by regulatory bodies. Third-party evaluations provide objective proof of compliance and reinforce trust.

These checkpoints ensure that your partner doesn’t just manufacture ointments—they produce confidence, safety, and regulatory reliability.

Communication, Logistics, and Final Selection

Building Trust through Clear Communication and Coordination

Even the most advanced facilities fall short without transparent communication and efficient logistics. The ability to respond quickly, deliver on time, and maintain operational transparency defines a manufacturer’s professionalism and dependability.

- Responsiveness: Track how quickly they reply to emails or calls during the inquiry phase—it reflects how they’ll handle issues later.

- Dedicated Contact Person: Having a single point of contact helps streamline communication.

- Location Advantage: Manufacturers located in hubs like Baddi, Ahmedabad, or Hyderabad offer better logistics and infrastructure.

- Transport Network: Accessibility to ports and highways ensures timely shipments, especially for export-oriented projects.

- Case Studies & References: Ask for case studies or client success stories that demonstrate reliability and problem-solving ability.

- Financial Transparency: Discuss payment terms, minimum order quantities, and penalties for delays to avoid future disputes.

- Facility Inspection: If possible, visit the plant to observe real-time production standards and workforce discipline.

Strong communication channels and clear documentation turn a business agreement into a long-term partnership.

Conclusion

Selecting the right ointment contract manufacturer in India is a strategic decision that determines your brand’s future credibility, market performance, and consumer trust. It’s not merely about cost—it’s about reliability, innovation, and shared commitment to quality. A capable partner brings more than production efficiency; they bring expertise, compliance assurance, and flexibility to scale your operations smoothly.

When you partner with a manufacturer who holds global certifications, invests in R&D, maintains open communication, and honors timelines, you gain an ally dedicated to your success. Such collaboration ensures that your ointment products stand out in a competitive marketplace—not only for their effectiveness but also for their consistency, safety, and presentation.

In the end, a great manufacturer is not just a vendor—it’s a growth partner who helps transform your product ideas into trusted, market-ready solutions that reflect your brand’s vision for quality and care.

Explore Related Blogs

Stay informed with our curated selection of similar blogs, offering expert perspectives on pharmaceutical trends, regulatory updates, and product innovations.

These articles are designed to help healthcare professionals, partners, and businesses stay ahead in an ever-evolving industry. Explore more to deepen your knowledge and make informed decisions.